Maritime News

Somewhere in the world’s busiest port of Shanghai, a container of fertilizer sits among tens of thousands of boxes, waiting for a ride to the U.S. It’s been on the dock for three months, trapped by typhoons and Covid outbreaks that have worsened major congestion in the global supply-chain network.

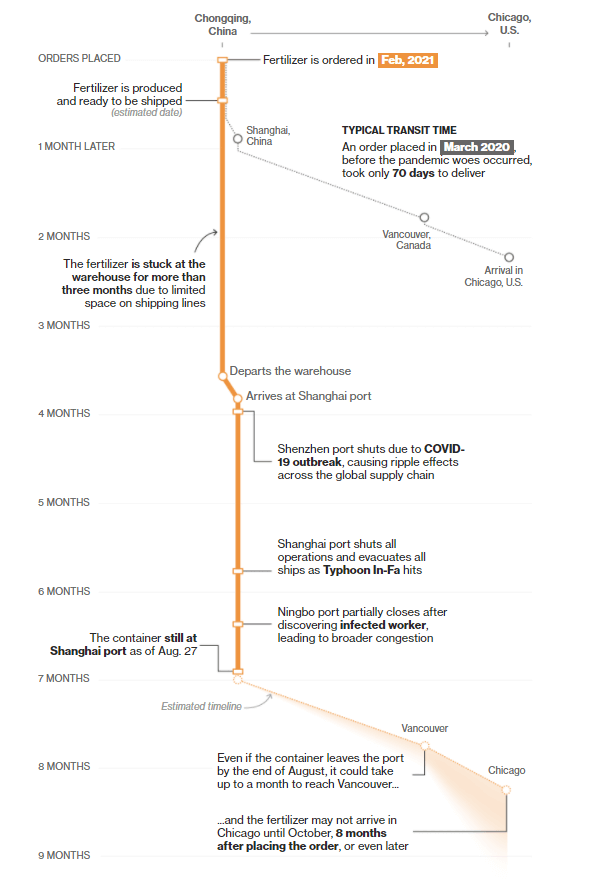

The fertilizer shipment has endured delays since the order was made in February, stretching a delivery that ordinarily would take weeks to more than half a year. And that time frame will keep expanding, as the goods have barely started the roughly 15,000 kilometer (9,300 mile) trek from central China to the U.S. Midwest.

From the U.S. to Sudan to China, containers have been lying at ports, railyards and in warehouses for most of this year as the pandemic rages on. That’s bringing more chaos to already overstrained shipping chains, adding to the challenge of putting Illinois corn on consumers’ tables and delivering millions of presents for the Christmas holidays.

An Arduous Journey

Covid outbreaks, extreme weather and the broader congestion in the global supply-chain network have stretched a delivery that ordinarily would take weeks to more than half a year.

This container has waited months in a warehouse amid a severe shortage of empty container boxes, travelled down the flood-prone Yangtze river and braved typhoon In-Fa when it slammed into East China. It faces even more delays when it finally reaches the U.S., where ports and railways are dealing with backlogs.

In an industry with 25 million containers and some 6,000 ships hauling them around the world, it’s easy to see disruptions as one big headache confined to the shipping industry. But each container that’s delayed is economic activity that’s restrained, heaping costs one box at a time on consumers and forcing companies to find other expenses to cut.

Source : Ann Koh | Bloomberg

Comments are closed.